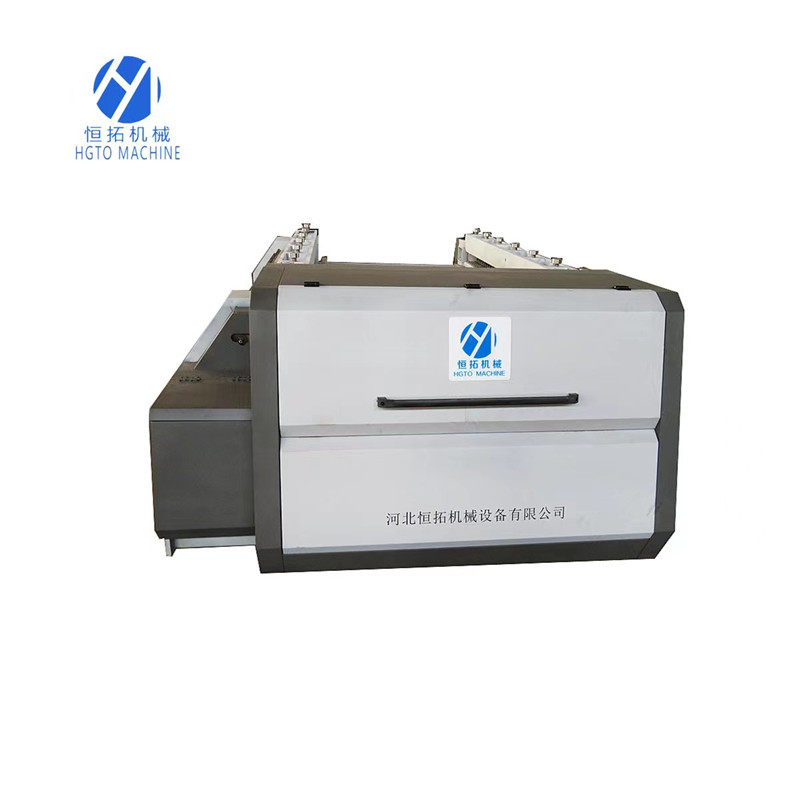

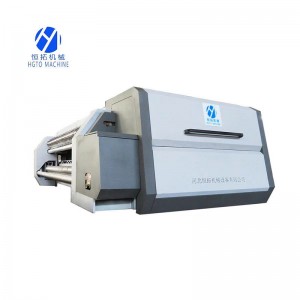

Horizontal Gabion Wire Mesh Making Machine

Video

Advantages of Horizontal gabion wire mesh machine

1. Reduce the investment cost by 50% VS heavy type, and provide production efficiency.

2. Adopting horizontal structure, the machine runs more smoothly.

3. Reduced volume, reduced floor area, greatly reduced electricity consumption, and reduced costs in many aspects.

4. The operation is more simple, two people can operate, greatly reducing the long-term labor cost.

5. Suitable for hot dip galvanized wire, zinc aluminum alloy, low carbon steel wire, electric galvanized, PVC plastic and other materials.

Application

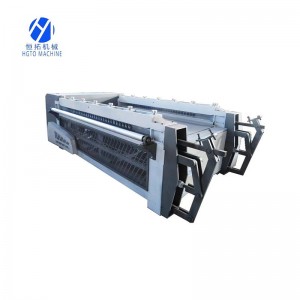

Gabion mesh machine is one kind of special equipment for twisting metal wire hexagonal mesh with big wire, big mesh and wide breadth.

The product has widely purpose, with its good corrosion resistance and oxidation resistance, serves well as strengthen, protection and temperature keeping materials in the form of mesh container, stone cage, isolation wall, boiler cover or poultry fence in construction, petroleum, chemical, breeding, garden and food processing industries.

gabion mesh machines (hexagonal wire netting machine) have been designed to make gabion mesh (hexagonal mesh) of various widths and mesh sizes. For high corrosion resistance, zinc and PVC, galfan coated wire is available.

Technical Parameter

|

Model |

Mesh Size |

Max

Width |

Wire Diameter |

Twisted Number |

Drive Shaft Speed |

Motor Capacity |

|

/ |

mm |

mm |

mm |

|

m/h |

kw |

|

HGTO-6080 |

60*80 |

3700 |

1.6-3.0 |

3/5 |

80-120 |

7.5 |

|

HGTO-80100 |

80*100 |

1.6-3.0 |

||||

|

HGTO-100120 |

100*120 |

1.6-3.5 |

||||

|

HGTO-120150 |

120*150 |

1.6-3.2 |

120+ |

|||

|

Dimension |

Weight:5.5t |

|||||

|

Remark |

Can be customized according to customer requirements |

|||||

Advantages

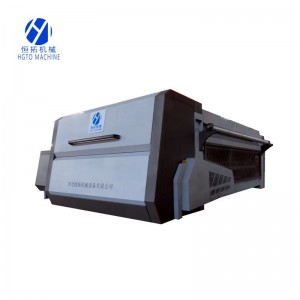

1. The new machine adopts horizontal type structure,Running smoother.

2. Its easy to operate this machine,just need 1-2 workers is ok.

3. Reduced volume, reduced floor area, greatly reduced electricity consumption, and reduced costs in many aspects.

4. Simple installation,No special technology needed.

5. Suitable for hot dip galvanized wire, zinc aluminum alloy, low carbon steel wire, electric galvanized, PVC plastic and other materials.

FAQ

Q: Are you really factory?

A: Yes, We are a professional wire mesh machines manufacturer. We dedicated in this industry more than 30 years. We can offer you good quality machines.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in ding zhou and shijiazhunag country, hebei Province, China.All our clients, from home or abroad, are warmly welcome to visit our company!

Q: What is the voltage?

A: To ensure each machine runs well in different country and region, It can be customized according to our customer’s requirments.

Q: What's the price of your machine?

A: Please tell me wire diameter, mesh size,and mesh width.

Q: What is your payment terms?

A: Usually by T/T ( 30% in advance, 70% T/T before shipment) or 100% irrevocable L/C at sight, or cash etc. It is negotiationable.

Q: Do your supply includes installation and debugging?

A: Yes. We will send our best engineer to your factory for installation and debugging.

Q: How long is your delivery time?

A: It will be 25- 30 days after received your deposit.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience of exporting. your customs clearance will be no problem..

Q: Why choose us?

A. We have an inspection team to check the products at all stages of the manufacturing process-raw material100% inspection in assembly line to achieve the required quality levels. Our guarantee time is 2 years since the machine was installed in your factory.